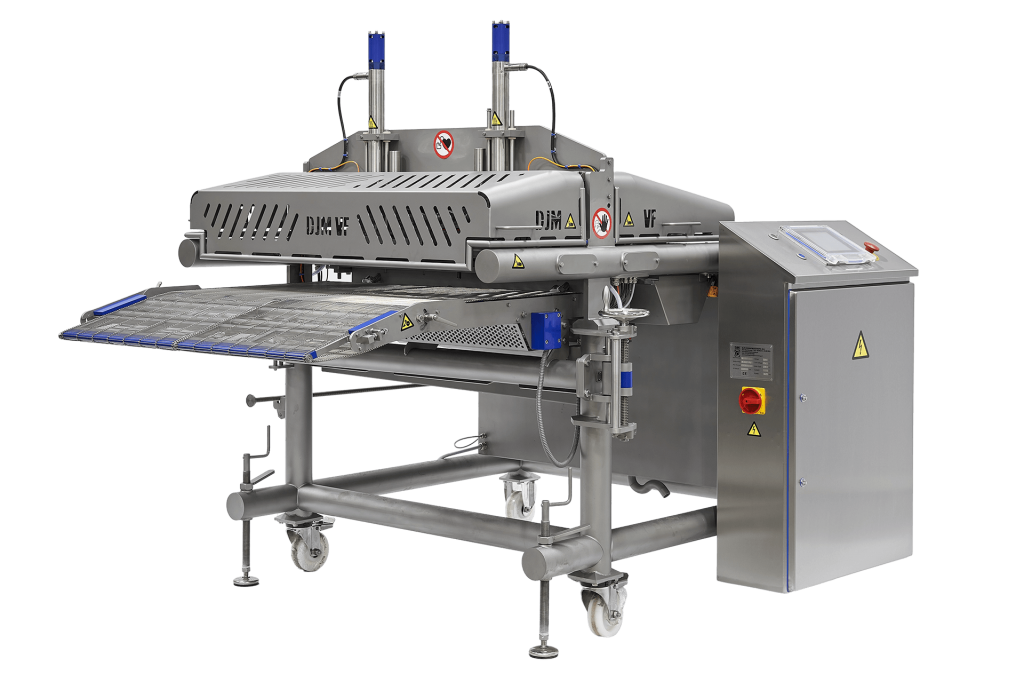

DJM’s co-extrusion machines are ideal for the production of (filled) snacks such as cheese balls, meat pies and other ‘3D Products’. They are unique in the world, which is illustrated by the fact that they can produce Scotch Eggs in one single process cycle.

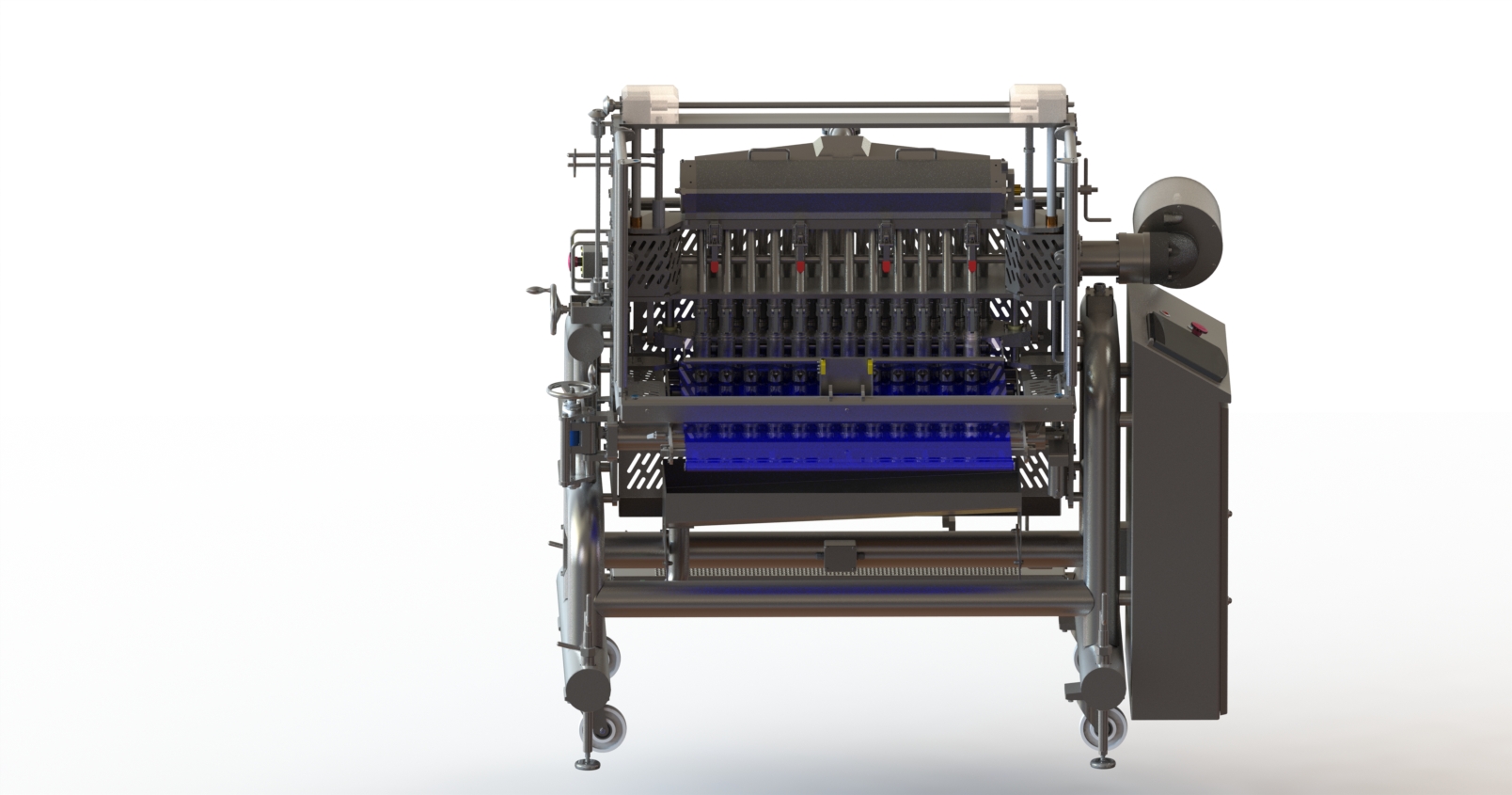

Simultaneous production, deploying up to 14 synchronous extrusion heads (or more in extended machine-versions), is reflected in a very high production capacity of up to 84,000 products per minute. Also the patented DJM pressure distribution system plays an important role in co-extrusion technology and forms the foundation for a high, constant transport speed, combined with low operating costs.